Research involving lubricant-impregnated surfaces

Some of the recent work on water-shedding surfaces involving the group now at the University of Edinburgh has been included in the sections on Water-shedding surfaces and Uses of water-shedding surfaces. Click on the thumbnails below to go to the relevant pages.

Below you can read about some other work of this group related to water-shedding lubricant-impregnated/liquid-infused surfaces.

Pinning-free evaporation

A droplet’s contact area decreases smoothly when evaporating on a lubricant-impregnated surface. This suppresses the coffee ring-stain effect.

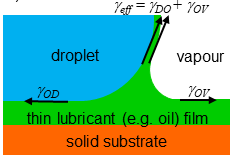

Liquid version of Young’s Law

The contact angle between a droplet and a thin layer of lubricant can be predicted from the lubricant-vapour, lubricant-droplet and droplet-vapour interfacial tensions.

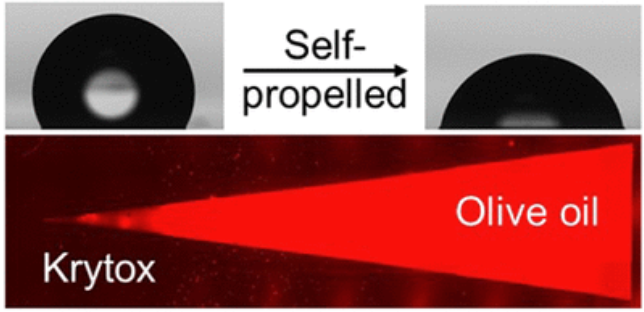

Droplet self-propulsion on biphilic liquid surfaces

Patterned liquid lubricant surfaces can demonstrate long-distance droplet self-propulsion, which sheds light on the interactions between liquid droplets and liquid surfaces.

Cheerios effect on SLIPS

The overlap from the lubricant skirt around a droplet on SLIPS can interact with the meniscus from a boundary. This provides a powerful force of attraction between the wall and the droplet.

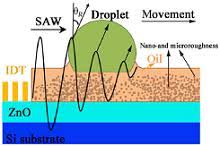

SAW-driven motion

A lubricant-impregnated surface coating can reduce friction between a droplet and substrate, allowing droplet motion to be driven by a surface acoustic wave (SAW).

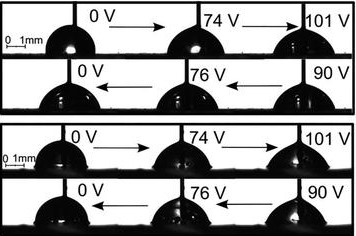

Liquid lenses on SLIPS

A SLIP surface allows a droplet to be smoothly and reversibly spread into a film or droplet with a smaller curvature by application of a suitable voltage. This allows the droplet to act as a variable-focus lens.

Liquid-liquid Interfacial Tensions

The contact angle on a lubricated surface predicts the liquid-liquid interfacial tension between the droplet liquid and lubricating liquid.

The Liquid Surface Zisman Plot

The critical surface tension of a solid was a key concept in the development of adhesives. A similar concept of critical surface tension of a liquid surface can be defined using SLIPS.

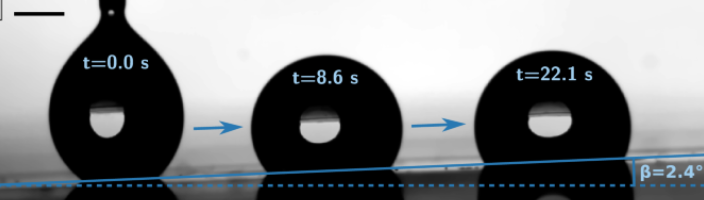

Droplets on Shaped and Gradient liquid Surfaces

Resistance to motion caused by direct contact between a droplet and a solid can be drastically reduced by preventing direct contact with the help of dual-length scale micro-structures and the concept of “liquid-surfaces”.