Superhydrophobic foams

A common approach to creating super water-repellent surfaces is to first make a rough structure. A hydrophobic coating can them be applied to the structure using surface chemistry. However, if the surface is rubbed or abraded, the coating is worn away. This removes the water-repellancy.

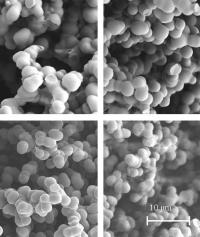

An alternative to using surface chemistry to create a hydrophobic surface is to use the sol-gel technique. Here, a foam is produced by a phase separation method. By varying the properties of the solution used in the process, the sizes of pores in the foam can be controlled. The pores in foams produced using MTEOS (methyltriethoxysilane) have hydrophobic surfaces throughout the foam. This means that if the foam becomes dirty and loses its super water-repellency, abrading it to remove the dirt renews the surface and restores the superhydrophobicity.

Read more about the process in the publication below.

Publication

Intrinsically super hydrophobic organo-silica sol-gel foams N.J. Shirtcliffe, G. McHale, C.C. Perry and M.I. Newton, Langmuir 19 (2003) 5626-5631

Further Reading

- Porous materials show superhydrophobic to superhydrophilic switching N.J. Shirtcliffe, G. McHale, M.I. Newton, C.C. Perry and P. Roach, Chem. Comm. 25 (2005) 3135-3137

- Superhydrophobic to superhydrophilic transitions of sol-gel films for temperature, alcohol or surfactant measurement N.J. Shirtcliffe, G. McHale, M.I. Newton, C.C. Perry and P. Roach, Maters. Chem. & Phys. 103 (2007) 112-117