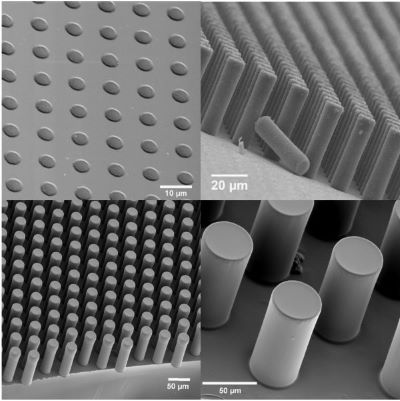

Polymer microposts

Circular pillars of various heights and diameters, deposited in square patterns.

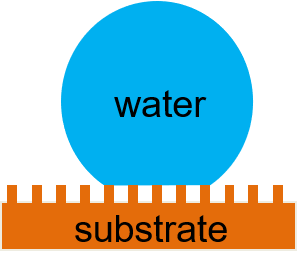

We can use a process borrowed from the microelectronics industry called photolithography to create a surface with a regular array of polymer microposts that are between one millionth and ten millionths of a metre in diameter. We can then apply a hydrophobic coating to create a superhydrophobic structure. The result is a microscopic version of a “bed of nails“, as we described here. Water droplets sit on top of the “nails” with a high contact angle, as illustrated schematically below.

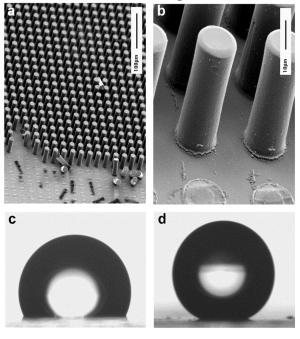

We can see from images (c) and (d) below that the contact angle of a droplet on top of the microposts is much higher than that of a droplet on a flat hydrophobic surface.

To create the polymer microposts, a light sensitive polymer liquid (a photoresist) is deposited onto a spinning substrate so that it forms a thick film. The photoresist is then exposed to intense light through a glass mask with a pattern of holes on it and this changes the properties of the film in selected locations so that some parts become insoluble in a special solution (a developer). The developer is then used to remove the parts of the film which were not exposed to the light, leaving behind microscopic posts. Finally, the surface is hard-baked to convert the posts into a durable surface. Read more about the process in the publication below.

Publication

The use of high aspect ratio photoresist (SU8) for super-hydrophobic pattern prototypes N.J. Shirtcliffe, S. Aqil, C. Evans, G. McHale, M.I. Newton, C.C. Perry and P. Roach, J. Micromech. Microeng. 14 (2004) 1384-1389